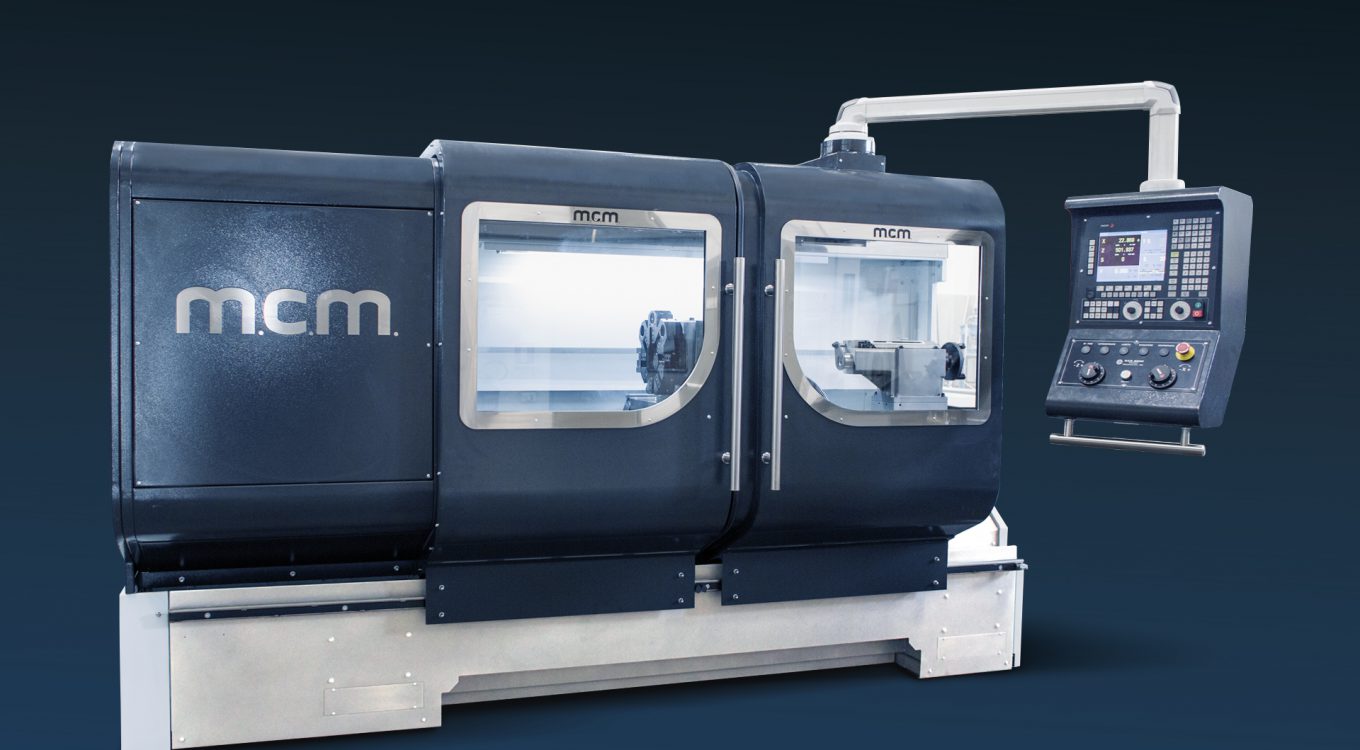

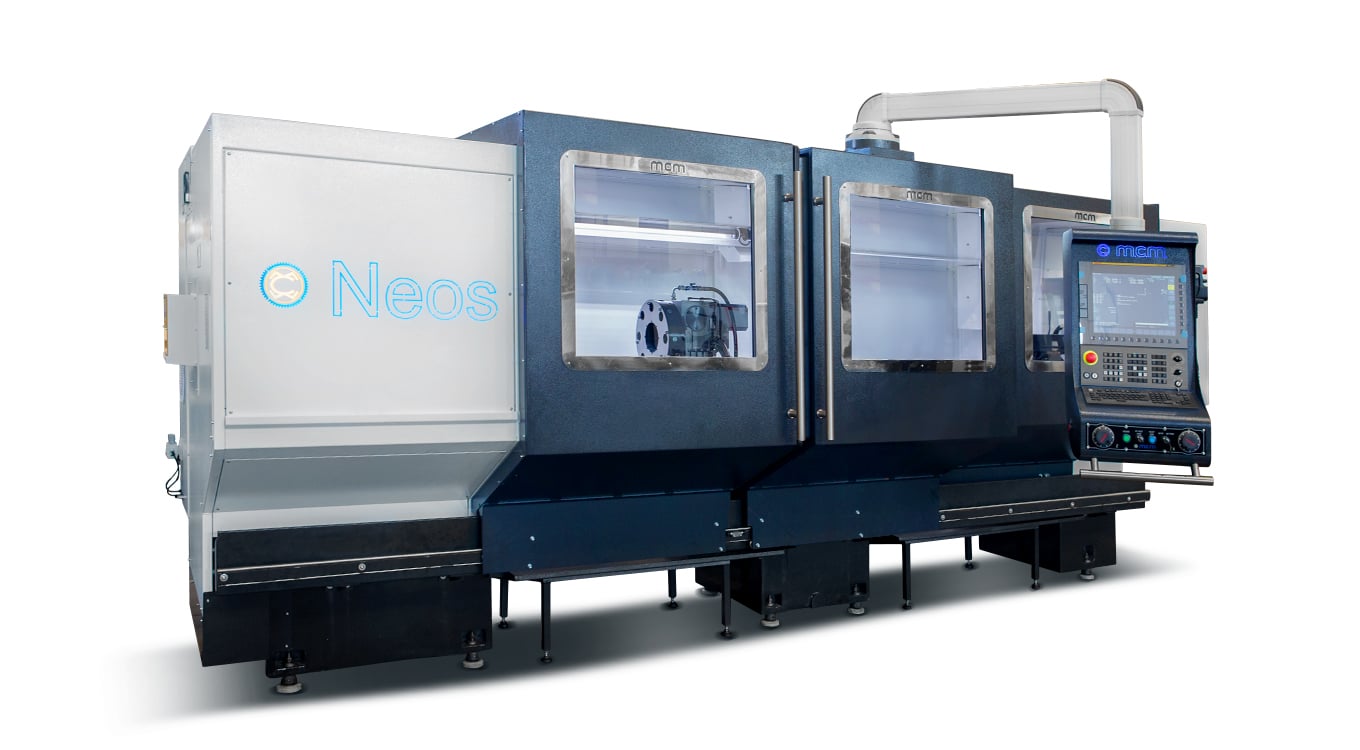

ATL NEOS evo

250 - 280 - 310 - 350 - 400

| Technical Specifications | 250 | 280 | 310 | 350 | 400 | |

|---|---|---|---|---|---|---|

| Height of centres | mm | 250 | 280 | 310 | 350 | 400 |

| Swing over bed | mm | 500 | 560 | 620 | 700 | 800 |

| Swing over cross slide | mm | 240 | 300 | 360 | 440 | 540 |

| Distance between centres | mm | 1 - 1.5 - 2 - 3 - 4 - 5 | ||||

| Bed width | mm | 400 ( Opt. 500 ) | 500 | |||

| Spindle bore | mm | 82 (Opt. 105) | 105 (Opt. 82 - 130 - 160 - 205) | |||

| Spindle nose | Camlock | 8" | 8" (11") | |||

| Spindle speed | rpm | 0:2200 | 0:1800 | |||

| Speed ranges (Automatic) | N. | 1 (2) | ||||

| Main motor power (S6/S1) | Kw | 22/15 (Opt. 26/18,5) | 26/18,5 (Opt. 33/22) | |||

| Cross slide travel | mm | 300 | 340 | |||

| X-Z axis rapid traverse | m/min | 12 | 12 | |||

| Tailstock quill diameter | mm | 85 | ||||

| Tailstock quill travel | mm | 150 | 200 | |||

| Tailstock quill taper | Morse | 5 | 5 | |||

| Max. weight between centers | Kg | 1500 | ||||

| CNC | Mod. | Fagor (Opt. Fanuc / Siemens / Heidenhain) | ||||

| Weigth | 225 | 260 | 300 | |

|---|---|---|---|---|

| ATL NEOS EVO x 1000 | Kg | 3600 | 3800 | 3900 |

| ATL NEOS EVO x 1500 | Kg | 3900 | 4200 | 4300 |

| ATL NEOS EVO x 2000 | Kg | 4300 | 4600 | 4700 |

| ATL NEOS EVO x 3000 | Kg | --- | 5400 | 5500 |

Standard equipment

- NC FAGOR or SIEMENS or FANUC or HEIDENHAIN

- Beds – Legs – Headstock – Tailstock – Carriages made of cast iron

- Induction hardened and ground guideways with hardness 50-55 HRC

- Spindle line supported by high accuracy bearings

- Carriages are sliding on antifriction material

- High accuracy and ground ballscrews on x and z axis

- Electric plant with low voltage control panel; it is placed in a suitable airtight cabinet. Make of components is Siemens and/or Schneider

- Automatic lubrication controlled by NC

- Enclosure with front sliding doors and work area lighting with led lamps

- Control programming panel, screen and handwheel mounted on a moving orientable arm (to place it on the best position for operator)

- Telescopic protections of cross slides

- Safety protections according EC standards

- Chip tanks on wheels

- Cooling system with electropump.

- Safety microswitch (to prevent collision) for X axis, Z axis and tailstock

- End-stroke for X/Z axis and tailstock

- 3 Colours lighting

- Heat exchanger for oil cooling in the headstock

- Air device on the tailstock to ease the displacement along bed

- Steady rest

- Set of service tools and wrenches – Manual – NC programming manuals – Machine built according to EC standards

Optional equipment

- Hydraulically or pneumatic operated chucks

- Manual self-centering chucks

- 4-independant jaw chuck

- Manual turret

- Automatic 4 position turret

- Automatic 8/12 position disc turret

- Automatic powered disc turret with 8/12 positions

- “C” with continuous movement by using the main motor or an independant motor.

- Hydraulically operated tailstock quill movement

- Tailstock with hydraulically operated locking/unlocking of tailstock base long bed

- Powered displacement of tailstock along bed

- Chip conveyor

- Hydraulically operated steady rest

- Steady rest with larger Ø than standard

- Follow rest

- Automatic speed change gear box Baruffaldi with mechanic ratio 1:4

- Boring bar support assembled on carriage

- Grinding unit

- Milling unit

- Portable electronic handwheel

- Air conditioner on electric cabinet

- Mist suction system

- Tool control probe

- Workpiece control probe

- Optical pressurized linear scales on X & Z axis

Would you like a quotation or more information for ATL NEOS evo

Fill out the form, we will reply as soon as possible